An innovative process

HIGH PERFORMANCE ALUMINUM FORGING

A unique casting technology of light alloys that involves the application of high pressure on the liquid state material during the solidification phase.

+ Quality

The complete escape of the air contained in the mold is ensured by the slow entry of the metal and by specially made “airs”.

+ Versatility

The compaction of the metal during solidification allows the recovery of the desired shape considering the transition from the liquid state to the solid state.

+ Competitiveness

The completely automatic production cycle is guaranteed by the technical solutions adopted on the machine lay-out.

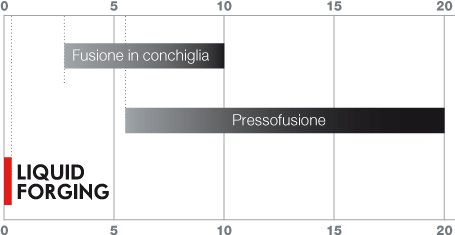

Cycle time much shorter than Squeeze Casting (ratio 1: 2.5)

+ Superiority

The density of the product is superior to any traditional casting process (gravity or diecasting) and equivalent to forging.

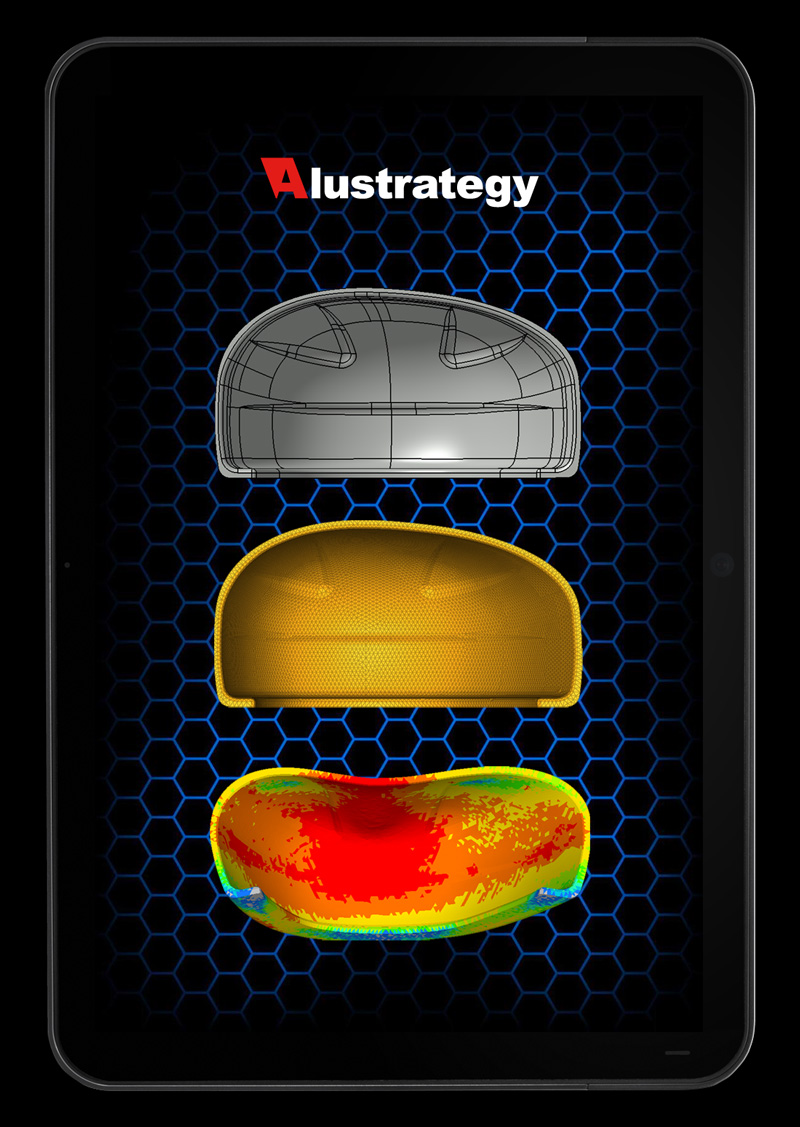

The harmony of safety

Our toecaps are equipped with an innovative design developed by our research and development department that uses the latest automotive and aerospace derivation technologies.

Our geometries are developed using FEM methodologies that optimize its shape according to the performance, making it harmonious safely.

The material is used only where it is necessary to achieve the target. The result is a light, ergonomic and above all performing toecap.

Liquid Forging quality

Structural integrity

Tighter dimensional tolerances than hot forged

Possibility to carry out heat treatments

Excellent micro-structure, due to rapid solidification following forced cooling of the tool

Suitable for all types of light alloys, including magnesium (6082, 7075, 2014,0 A356, AlSi4.5, AlSi9, Magsimal, Silagont, etc.)

Possibility of producing parts with inserts

Possibility of obtaining complex geometries

Possibility of producing parts in a weight range from 40g up to 10 kg

The right amount of liquid metal becomes the piece

Possibility of creating multi-cavity tools with significant reductions in cycle time

Possibility of having different geometries in the same tool

Cost positioned between the shell casting and the die casting

Forging processes in comparison

Conventional

Hot Forging Process

1. MELTING

• Melting Furnace

• Degas

• Filter

CASTING

2. DC CAST

3. ULTRASONIC INSPECTION

4. HOMOGENIZATION

5. EXTRUSION

• Scalping

• Preheat

• Extrusion

• Press

6. STRAIGHTEN & CUT

7. FORGING

Liquid Forging

Process

1. MELTING

• Melting Furnace

• Degas

• Filter

CASTING

2. LIQUID FORGING

Our LIQUID FORGING technology is an Alustrategy patent

Porosity

Percentage of porosity of the different technologies.

Absence of porosity with LIQUID FORGING technology

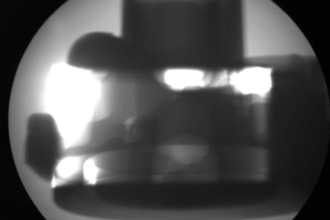

Analysis and structure

Transfer Case

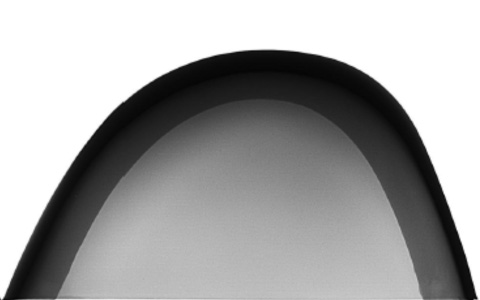

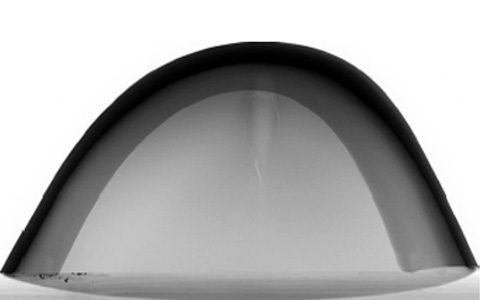

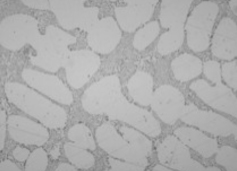

The radioscopic images illustrate some examples of parts produced by our technology of liquid forging, the absence of porosity, microporosity, blowholes, cracks and crystallizations (characteristics common to entire production batches).

TOECAP pre-crash test

TOECAP post-crash test

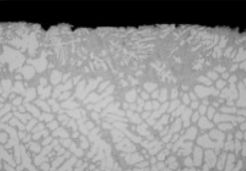

The microscope test shows how the microstructure at the surface of the casting jet is very fine, due to the very fast cooling of the liquid.

The interdendritic eutectic solidification microstructure is finely modified.

The core structure has a high dendritism, with average DAS values of about 18 µm, an index of rapid cooling.

Applications

Suspension components, parts of braking systems, mechanical supports, etc.

Steering bases, rocker arms, engine mounts, connecting rods, etc.